MATT STERBENZ LAUNCHES NEW SKI BRAND, WNDR ALPINE

Matt Sterbenz, the founder one of freeskiing’s most beloved brands, 4FRNT, announced today that he’s spearheading the launch of a new one, WNDR Alpine, which comes with a series of interesting and throught-provoking technological twists.

Golden, B.C. Photo by Carson Meyer

A highly respected figure in the sport, Sterbenz spent 16 years working with athletes to develop some of the most exciting and progressive ski shapes in history at 4FRNT, before selling the brand to Jason Levinthal, the legendary founder of Line and J Skis. After a year of the two titans of the ski manufacturing world teaming up to work together, Sterbenz left 4FRNT for a job with a biotechnology company in an effort to take on something new, before discovering that his new path would inevitably lead him back to his roots.

Rogers Pass, B.C. Photo by Carson Meyer

A few weeks ago, I had the chance to sit down with Sterbenz—who on a personal note, helped give me my start in the ski industry by hiring me as 4FRNT’s first-ever sales rep—on the eve of making my way to Whistler for summer camp, where ironically, we first met and began working together. During our nostalgically timed discussion, we chatted about what he’s been up to since leaving 4FRNT, what WNDR Alpine is all about, why he started it and how it differs from other brands, and how he feels about coming full circle. For anyone who loves ski technology, and skiing in general, it’s a must-read. —JEFF SCHMUCK, EDITOR

So let’s start things off by having you let everyone know what you’ve been up to since leaving 4FRNT.

I was fortunate enough to join a materials innovation company called Checkerspot, based out of Berkeley, California, which specializes in biotechnology. Their technology is rooted in microalgae, and prior to my encounter with these folks I didn’t have any real understanding of how microalgae played a part in materials whatsoever. So it’s been a fun learning curve, and I feel really fortunate to be able to provide them with a service of my know-how and applications of materials, while at the same time going through a crash course in microbiology and organic chemistry so that we can reverse engineer how materials get created.

Photo by Erika Dimmler

What made you want to work for them?

It was chance to explore a dimension that I hadn’t really had any visibility into as a ski builder. I started my profession as a freeskier tinkering with ski shapes while skiing for Fischer way back in the day, when we were still just defining what the sport of freeskiing was all about. And then through starting 4FRNT and collaborating with my peers to develop ski shapes for them, we started to really look at the possibilities two dimensionally. As in, how can we change the way a ski initiates its turn in a harder snowpack, or how can we increase surface area to get more of a surf-like experience in a softer snowpack. We went from building the initial 4FRNTs, which were all mountain twin-tips, which was a novel concept in itself at the time, since twin-tips prior to that were solely for the park, to designing a competition park and pipe ski with Steele Spence and Niklas Karlström, to working on backcountry and big mountain models with Vinnie Dorian, Eric Hjorleifson, CR Johnson and Wiley Miller, and then eventually World Cup pipe skis for David Wise. It was a cool experience to come full circle on the two dimensional philosophy of how we could affect the ski experience through different shapes and geometry. So leaving 4FRNT kind of felt like a bit of closure for me in terms of what I had achieved, and it wasn’t something I did intentionally. It was just kind of how nature took its course. I had decided to transition the management of the company, which eventually lead to the sale to Jason Levinthal, at which point we converted the business model from wholesale retail to direct-to-consumer, which was really exciting, and working with Jason was very satisfying for me. But then the opportunity to work with Checkerspot presented itself. First by them just approaching me about their technology while I was at 4FRNT, and me saying to them, “Oh sure, send me some materials to see if they can be incorporated into a ski’s production.” But it wasn’t something that me and my peers were really focused on at the time, because we were just playing in the sandbox that was provided to us from a materials and manufacturing standpoint. But as time went on, what Checkerspot was saying and doing sparked a lot of curiosity for me in terms of being able to reimagine the types of materials that go into skis, and I found it quite fascinating, so it was like, “Ok, tell me more.” Then we started to talk about the technology platform of microalgae and how that naturally converts to oil through fermentation, and how that oil can be a direct replacement for petroleum, and even improve upon its performance. This science-based approach with microalgae gives us a very pure molecule to build a material off of, which gives us novel characteristics and a variety of different ways in which we can ensure that we can meet specific characteristics for specific applications. And that’s kind of when the light bulb flipped on for me, in thinking that we could build better materials for skis derived from microalgae, which is a renewable resource. So I kind of jumped into it with these guys, because I saw it as an opportunity to start looking at ways in which we could design skis three dimensionally. I spent the last 16 years being focused on the outline geometry of skis, but now I could start looking within the ski itself and reimagining a new supply chain that could provide a pretty unique benefit to many different aspects of a ski’s construction. So on kind of a whim, I decided to start working with these guys, and it’s been a pretty cool experience to drop in on something totally new.

Photo by Xan Marshland

It’s pretty obvious that you’ve already learned a lot during your time with Checkerspot. How rewarding has that been for you personally?

It’s been fascinating to learn a completely new base of studies. I kind of circumvented chemistry and biology the best I could through college, as it wasn’t a field of knowledge that I naturally gravitated towards. I was having a better time studying art, business, marketing and design. But as I’ve gotten older my palette has matured and I’ve obviously become a little more serious. So it’s been really unique to kind of study under the very accredited industry professionals in biotechnology and materials science at Checkerspot. I feel really fortunate to have been welcomed into this community, of which my resume certainly doesn’t naturally allow that kind of networking connectivity to.

Rogers Pass, B.C. Photo by Carson Meyer

So on the heels of all this, you’ve got some big news to announce: you’re launching a new ski brand through Checkerspot called WNDR Alpine. What made you decide to further come full circle on that?

It became obvious to us that applying our technology within a brand that we controlled and were able to cultivate was a necessary first step. After briefly speaking with some of the industry folk who I have long connected with and have a ton of respect for, I realized that their business perspective isn’t the same as what our focus is about. And that’s no diss on the direction that the industry is trending. It’s just that our focus is too far out there for others to naturally gravitate to upon first impression. Similar to how I approached my initial conversation with Checkerspot, which was, “Yeah send me some materials and I’ll see if I can glue up some skis with it,” so has been a lot of the reaction from the industry when I present them with technology that converts microalgae into oil and you can build a variety of different polyurethane materials from it. The most sophisticated response I got from anyone that I presented the technology platform to at the ski show was, “What does it smell like?” And I found that to be a really funny but somewhat of an appropriate reaction, because this really is coming out of nowhere, but at the same time a lot of the trends in the industry right now certainly are built on perspectives of sustainability and everything we can do to help slow climate change, which adversely affects our ski season. So if you look at the supply chain in ski manufacturing right now, we’re all sourcing the same petrochemical plastics, composites and steel from the same three suppliers worldwide. And even they are diversified, where snow sports materials is only one small division within the larger scope of their business. But a lot of the big ski brands and factories out there really only want to build skis out of materials that they’re comfortable with, and because they’re so close to the source of those suppliers, there’s not a lot of appetite for skis moving away from those supply chains. And historically, it’s been hard to explore a variety of new materials without cost being a driving consideration. So after attempting to breathe in a new perspective by trying to get people to start re-imagining an origin of a material that can be applied to the constructs of a ski that has never been seen or tested or thought of in the past, I realized that we just had to do it ourselves. We’re going to have to build a brand, and we don’t need a huge portfolio of products, but we need to prove to the industry and the consumer that this technology is relevant and beneficial. And that once we are able to build a product, we could use that as our vehicle to introduce this evolutionary technology.

Photo by Carson Meyer

How will this technology help WNDR Alpine differ from other ski brands on the market?

So right now we’re starting with the ski core and applying a high-density algae composite to it to dampen core vibration as well as increasing the bulk strength-to-weight benefit, all done so with a specific focus on backcountry skiing. And as we continue to evolve we’ll use the algae platform to reimagine how we can replace other materials in a ski, and the ski will serve as a vehicle to showcase how we evolve technologically. And so every year that we bring skis to market there will be an increase of bio-based material in the overall composition, and I think that’s really exciting for not only the technology team back in Berkeley, but also for the consumers to see what else can be of benefit. If we’re reimagining the constructs of that particular material, we can ask ourselves, is that material performing in a way that provides ski-specific benefits? Because there’s some materials we use in skis today that have no performance attribute whatsoever. Take sidewalls for example. They’re there to be a moisture barrier for the ski core, and normally that’s ABS plastic, which has very little performance attributes, but because it doesn’t allow water to pass through it and bonds, it’s a “suitable” material that we use today. So could we perhaps improve the performance of that and other materials, while reducing some of the toxicity that goes into the making of some of those materials? Could we reimagine the application of a material that’s coming from a source or energy that’s more aligned with our own environmental ideals? We’ve all experienced the realities of climate change by now, and we know we need to think differently about our personal impact on earth. There’s guilt around every corner, when you fly somewhere, when you drive somewhere, and so on. So it’s cool to be able to bring this technology to skiing, because it’s not a typical industry that would get access to this type of innovation. To have a team of scientists working on ski-specific material applications as a proof-of-concept business unit within the overall schematic of Checkerspot’s organization is exciting, and really provides that third dimension of ski construction and design, which all skiers worldwide should have the opportunity to play with.

Photo by Carson Meyer

How many models are you planning to produce to start?

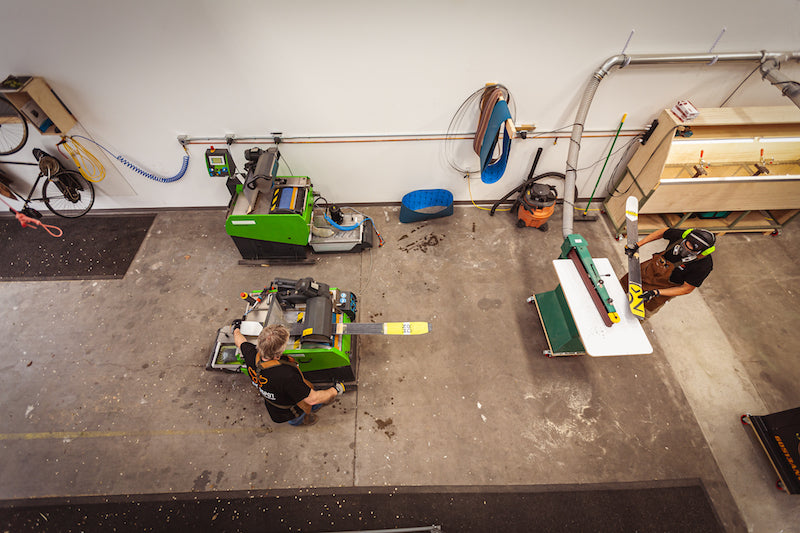

Initially super humble: one model, one width, in four lengths. We don’t want to discriminate towards those who are 5’9 and above, nor do we want to discriminate against men versus women, but we have to be mindful of the fact that we can only do one thing at the moment, and we want to make sure we do it right. So the debut model is going to be called The Intention 110. It will come in a 171, 178, 185 and 192, with a roughly 20-metre sidecut. I feel like the shape has some really great, universal characteristics, and WNDR Alpine is solely focused on backcountry skiing, so we want to make sure the ski is going to be first and foremost a really valuable and trusted tool in the backcountry, both on ascent and descent. But we want it to be playful, and I think the thing that will really separate us in our current capacity is that due to the fact these are all built right in our Design Lab in Salt Lake City, we can serial produce a variety of camber profiles for changing snow conditions. And that’s something that a lot of the large-scale ski manufacturers, due to the rigidness of their tooling constructs and distribution models, don’t really have the freedom and versatility to do. So we designed a tooling application and a mold that accommodates the ability to adjust camber profiles in the same size skis. So while we have one single model in four lengths, each of those lengths will be available in positive and reverse camber profiles. And I would like to have this type of option continue on for future model introductions. Right now our chartered course is, again, exclusively focusing on the backcountry experience, and introducing three ski shapes in three waist widths that cover the gamut of backcountry terrain, and then allowing lengths to accommodate the breadth of skier types out there and then having a variety of cambers so we can dial in their personal preference that way. But we don’t want to try to be a big, 10-15 model ski brand, where we’re racing down corduroy under the chair or hanging out in superpipes, and at the same time touring out of backcountry lodges and getting into high-elevation mountaineering type of travel.

And is that where you see the brand in five years? A handful of models, opening consumers and other manufacturers’ eyes to the technology, and potentially getting some of it in their skis?

Sure. I put some pen to paper on a five-year plan, and I can say most sincerely that our goal is to position WNDR Alpine as a trusted backcountry brand in winter sports. And I use the term “winter sports” because I don’t necessarily think it needs to be exclusive to skiing. I would like to see the technology eventually lead into snowboards as well, but again, we’re keeping a tight focus on backcountry specific geometries and functionalities. So we’re going to start with skis, and once we’ve proved certain design elements, then we can start to explore how those could potentially cross over into snowboarding. So in five years, I see us having a tight, three-piece quiver of skis, a three-piece quiver of snowboards, and hopefully being able to deliver some of the technology to other partners in the industry so they can benefit from this platform as well. If asked, “are we willing to open this technology up to other companies so they can benefit from it?” The answer is absolutely yes. We want to generate revenue from our product and development, and the goal of this technology first and foremost is performance, and we want to share that with others. But we do want to shoulder the burden for some partners, so they don’t have to go through the some of the learning curves that we are willing to go through ourselves with our own brand, in order to identify how the technology can be of immediate benefit to them.

Photo by Carson Meyer

When will The Intention 110 be available, and how will people be able to get their hands on a pair?

They’ll be debuting in early July. We wanted to get the product up and running and available for pre-order right away, so we’re stacking inventory already in Salt Lake City, and this fall will see the first limited release through direct-to-consumer sales online. The website is live at wndr-alpine.com, that’s WNDR without vowels, as a nod to my past with 4FRNT (laughs), and our story is up there. Our current projection is to make a few hundred pairs of skis, so we can get those out to early adopters who really want to experience something new and unique in comparison to skis they currently own or have owned in the past. We’re not saying that people should drop in on WNDR Alpine exclusively right now, because we know we have a limited offering to start, but we’re definitely asking for a piece of that quiver. Let us show you what we’re up to, and how that performance characteristic may feel a little different to you.

And lastly, how does it feel for you personally to launch another ski brand after being the founder of such a well-loved and now legendary one in 4FRNT?

(laughs) It’s funny. You know, it’s like when you run into a buddy who’s already got kids, and they just so happen to have another kid on the way, and they kind of laugh about it. You’re about to bring a soul into the world, which comes with a shit ton of responsibility, but it’s just kind of funny how things happen sometimes, because starting 4FRNT had a lot of similarities to early parenthood. So I do find it funny, and I’m sure that other people who have exited brands and then found themselves starting a new one, like Jason [Levinthal], after his experience with building Line, and then starting J Skis, I’m sure he kind of chuckled at the idea that he was getting back into skiing. I felt like after leaving 4FRNT that I had served my time well in the ski industry, but it just so happens that guys like us have a deeply rooted passion for this industry, which has been built up through years of interactions with skiers and the design elements that have made some of our greatest days ever. And you can’t shake that bug.

For more on WNDR Alpine, visit wndr-alpine.com.